Lesson Title: Demand Planning in the Chemical Industry

Lesson Description:

Demand planning in the chemical industry involves forecasting customer demand amidst complex challenges such as market volatility, specific customer requirements, regulatory changes, and shifts in global economic conditions. Effective demand planning is critical for maintaining profitability, competitive advantage, and operational efficiency by accurately predicting future market conditions and customer needs.

Lesson Learning Objectives:

By the end of this lesson, participants will be able to:

-

Identify and describe the unique challenges associated with demand planning in the chemical industry.

-

Understand and apply statistical forecasting techniques complemented by expert market insights.

-

Evaluate the benefits of collaborative demand planning processes.

-

Develop strategies to handle regulatory changes and market volatility effectively.

Lesson Key Points:

-

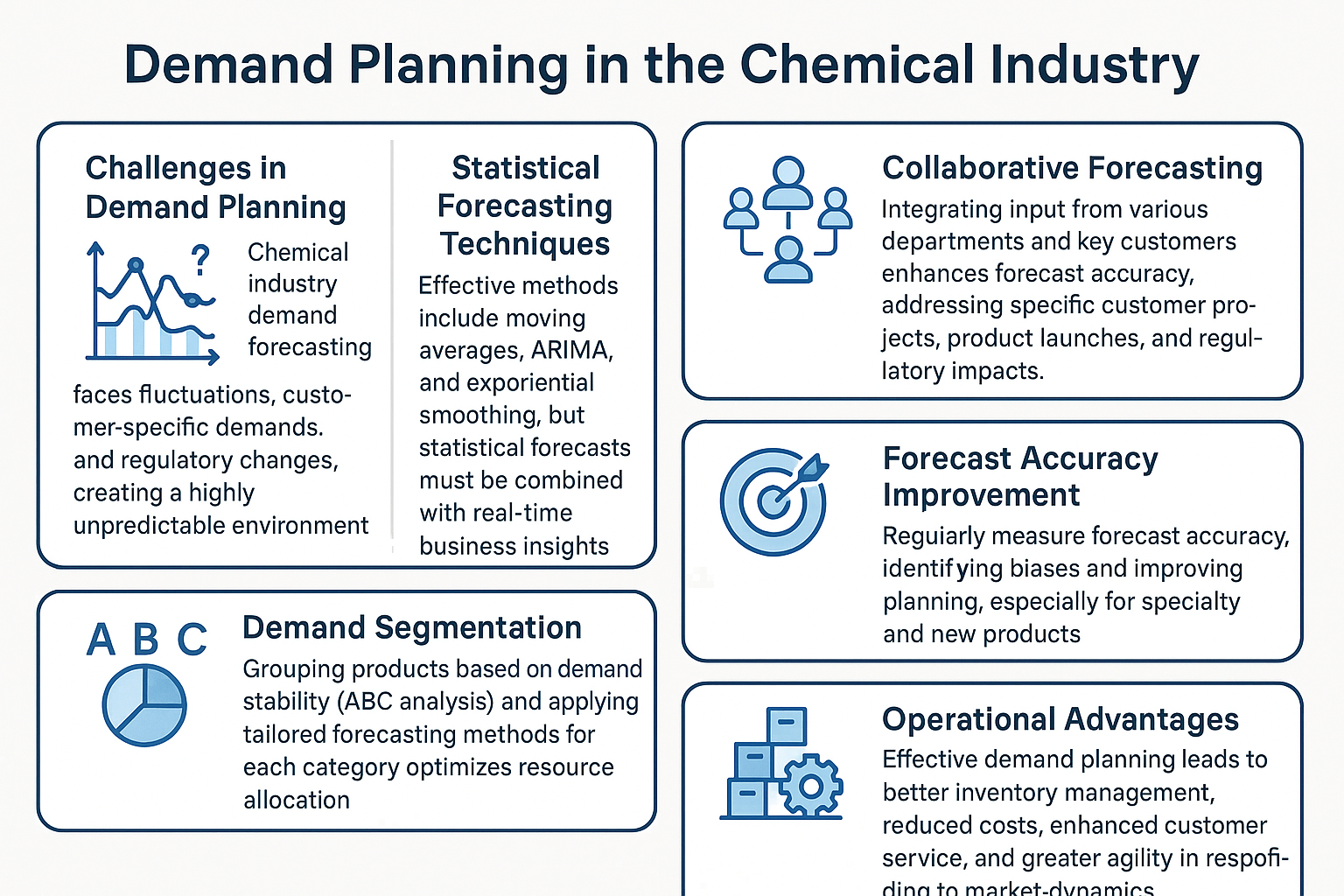

Challenges in Demand Planning: Chemical industry demand forecasting faces fluctuations, customer-specific demands, and regulatory changes, creating a highly unpredictable environment.

-

Statistical Forecasting Techniques: Effective methods include moving averages, ARIMA, and exponential smoothing, but statistical forecasts must be combined with real-time business insights.

-

Collaborative Forecasting: Integrating input from various departments and key customers enhances forecast accuracy, addressing specific customer projects, product launches, and regulatory impacts.

-

Demand Segmentation: Grouping products based on demand stability (ABC analysis) and applying tailored forecasting methods for each category optimizes resource allocation.

-

Forecast Accuracy Improvement: Regularly measure forecast accuracy, identifying biases and improving planning, especially for specialty and new products.

-

Regulatory Preparedness: Stay proactive by monitoring regulatory landscapes, preparing for shifts that can significantly impact chemical demand.

-

Operational Advantages: Effective demand planning leads to better inventory management, reduced costs, enhanced customer service, and greater agility in responding to market dynamics.

Lesson Summary:

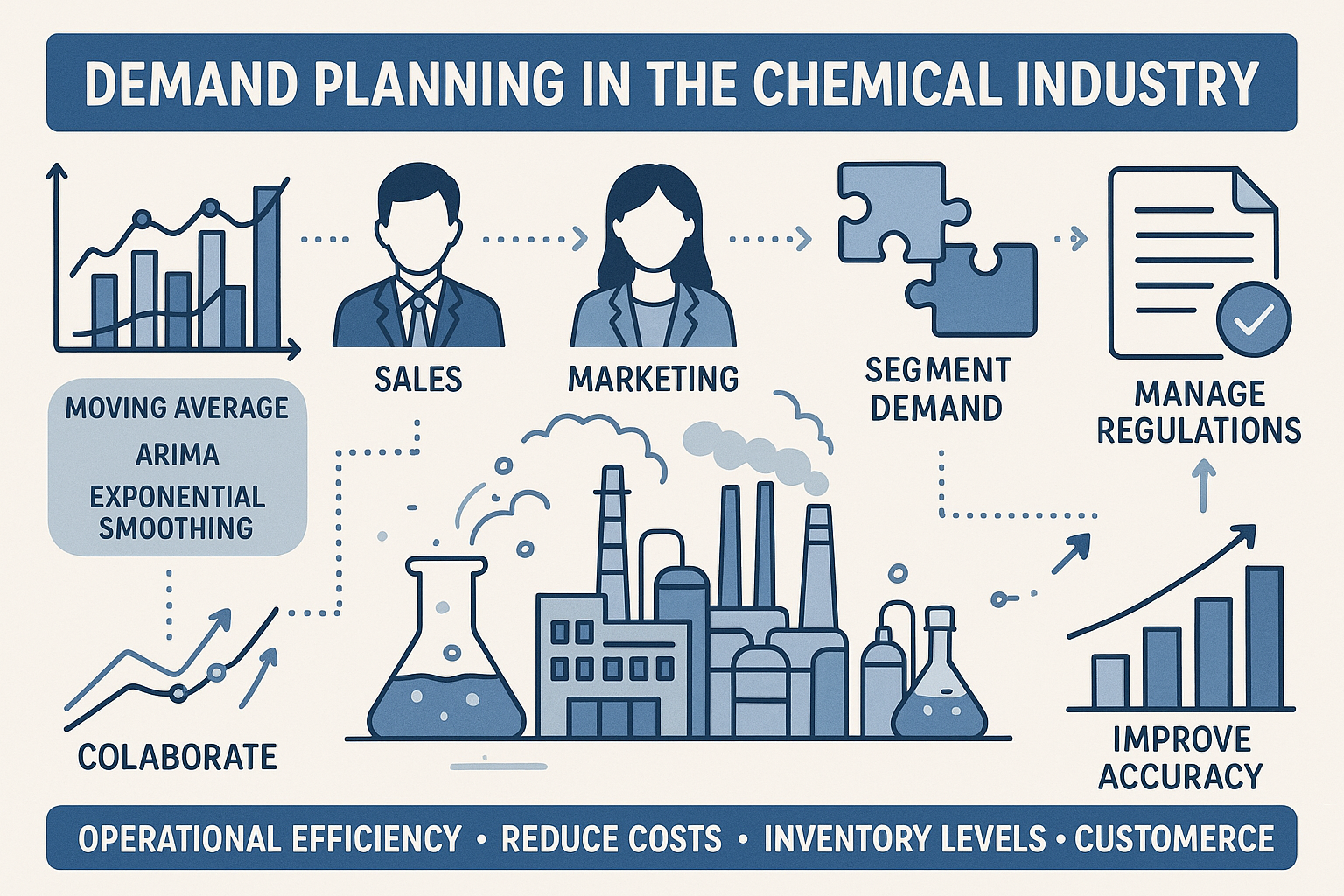

Demand planning is critically important in the chemical industry due to its inherent complexity stemming from fluctuating market demands, specific customer needs, regulatory developments, and unpredictable economic conditions. Successfully navigating these challenges requires a robust forecasting approach that combines statistical methods—such as moving averages, ARIMA, and exponential smoothing—with collaborative insights from sales, marketing, and customer interactions. The integration of collaborative processes significantly enhances the accuracy and responsiveness of forecasts. Chemical manufacturers must strategically segment demand based on product volatility, continually measure and refine their forecasting approaches, and proactively manage regulatory changes. Ultimately, effective demand planning equips chemical companies to improve operational efficiency, reduce costs, maintain optimal inventory levels, and deliver superior customer service.

Lesson Takeaways:

-

Effective demand planning in the chemical industry requires careful handling of complexity, unpredictability, and regulatory changes.

-

Robust statistical forecasting techniques, supplemented by real-time market and expert insights, are essential for accurate predictions.

-

Cross-departmental collaboration significantly improves forecasting precision, enabling better responses to market conditions.

-

Ongoing measurement of forecast accuracy is critical to continuous improvement and inventory optimization.

-

Proactive preparedness for regulatory and economic shifts enhances strategic agility and helps maintain competitive advantage.