Lesson Title: End-to-End Supply Chain Planning in the Chemical Industry

Lesson Description:

End-to-end supply chain planning in the chemical industry covers the complete spectrum of activities from sourcing raw materials globally to delivering finished products safely to customers. Due to the complex nature of chemical processes, strict regulatory requirements, and volatile market conditions, effective planning is vital for profitability, safety, sustainability, and customer satisfaction.

Lesson Learning Objectives:

By the end of this lesson, participants will be able to:

-

Describe the complexities and key elements involved in chemical supply chain planning.

-

Understand how demand forecasting impacts supply chain decisions.

-

Recognize the importance of integrated planning processes like S&OP and IBP.

-

Develop strategies for optimizing inventory, production scheduling, and logistics in the chemical industry.

Lesson Key Points:

-

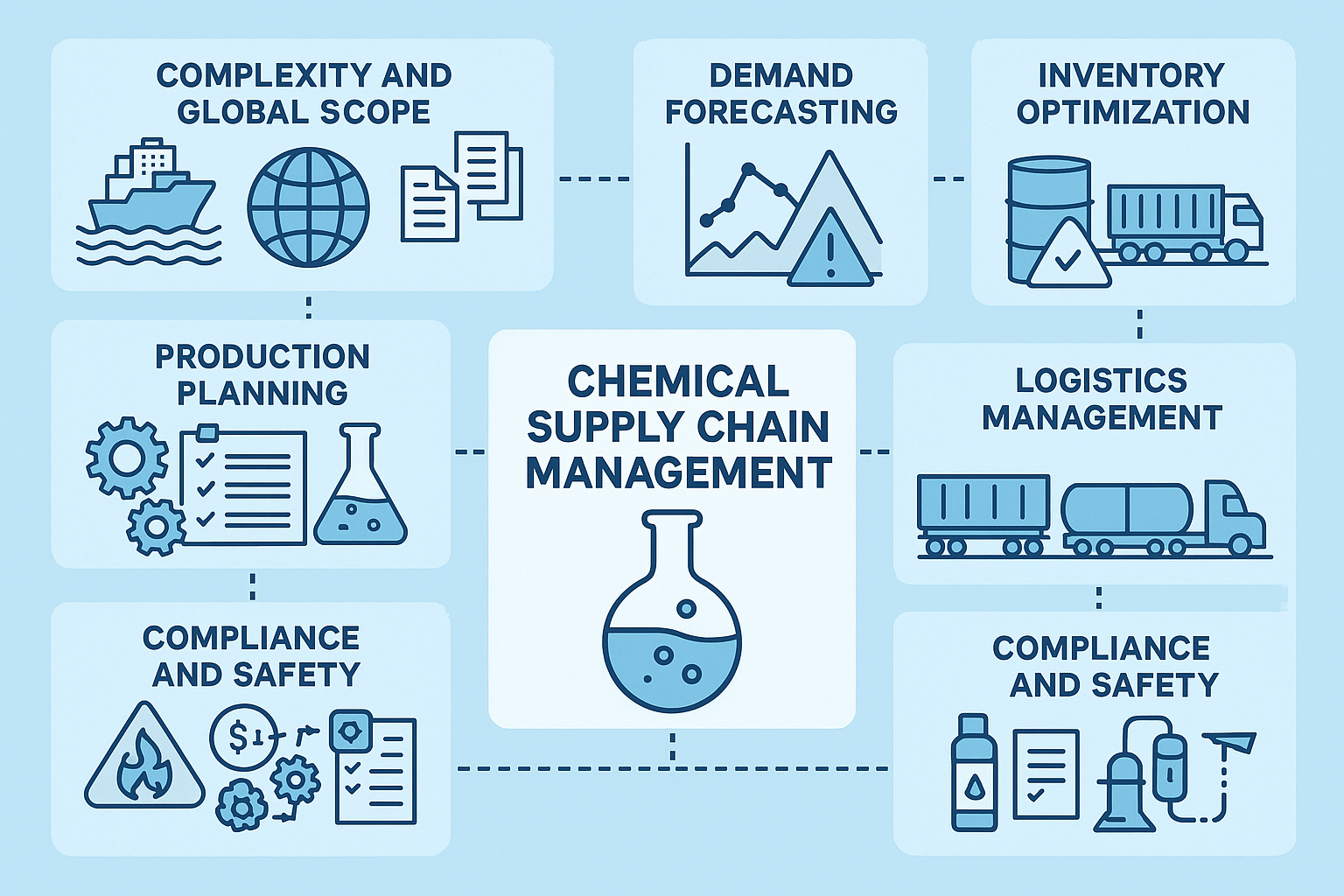

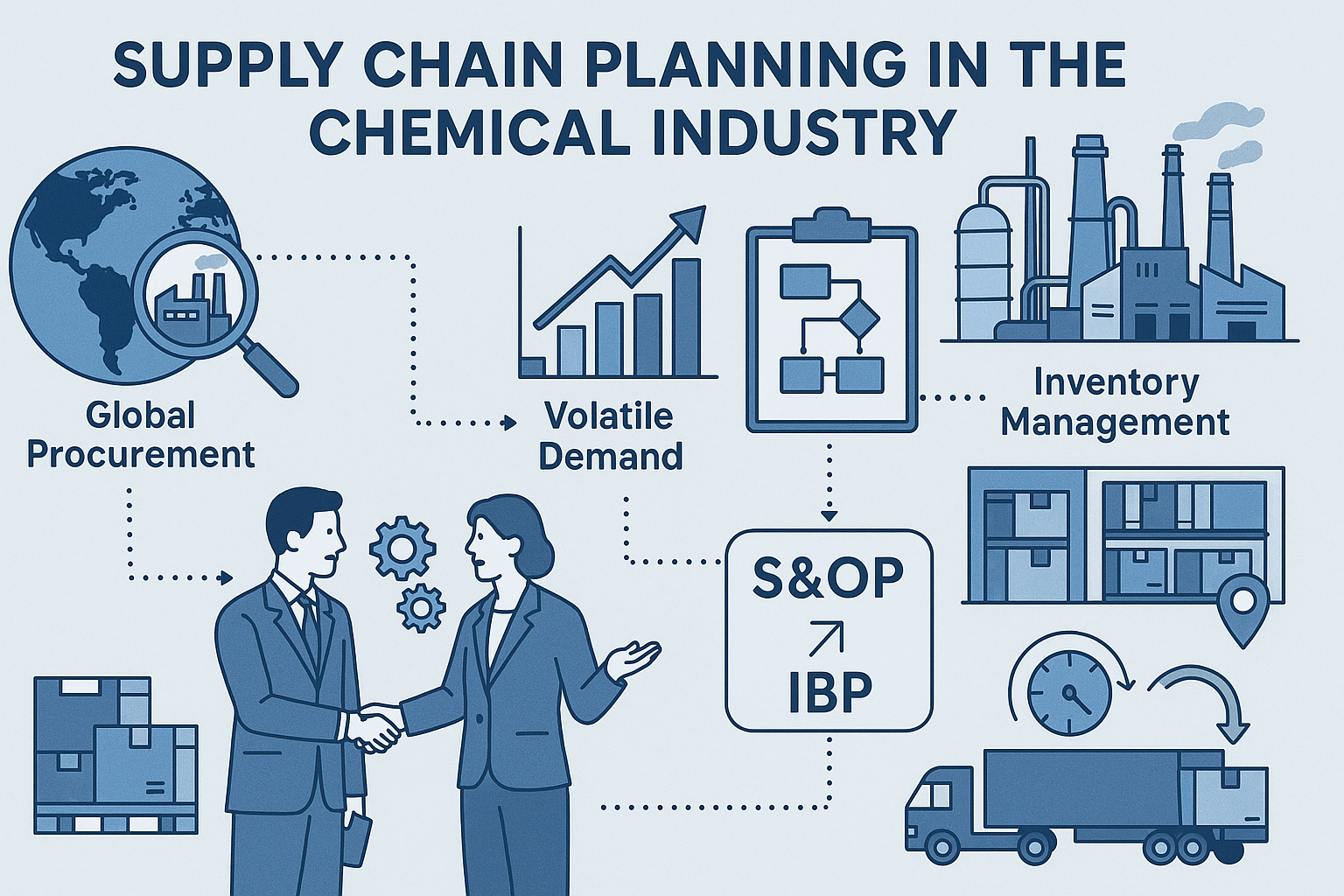

Complexity and Global Scope: Chemical supply chains involve global sourcing, intricate logistics, and compliance with varied regional regulatory frameworks.

-

Demand Forecasting Challenges: Volatile raw material prices, unpredictable supply routes, and long lead times make accurate forecasting challenging yet critical.

-

Production Planning: Effective scheduling involves balancing batch and continuous processes, optimizing production campaigns, and managing multiple outputs like co-products and byproducts.

-

Inventory Optimization: Critical to balance service levels, costs, product shelf-life, and safety risks, ensuring regulatory compliance.

-

Integrated Planning (S&OP and IBP): These frameworks ensure alignment among sales, operations, procurement, and finance, crucial for managing chemical industry-specific constraints.

-

Logistics Management: Optimal transportation mode selection (road, rail, sea, barge) and multimodal solutions are essential for efficient global product delivery.

-

Compliance and Safety: Strict adherence to hazardous material regulations, ensuring safe handling, storage, transportation, and inventory management.

Lesson Summary:

Effective supply chain planning in the chemical industry demands meticulous attention to the intricate details of global sourcing, production complexities, and strict regulatory requirements. Given the industry’s inherent unpredictability and complexities—such as long procurement lead times, volatile demand patterns, multiple product outputs from single processes, and the critical importance of regulatory compliance—comprehensive planning strategies are crucial. Companies must integrate accurate demand forecasting with detailed production schedules, carefully balance inventory levels against service and safety requirements, and select logistics options that optimize efficiency and compliance. The adoption of collaborative frameworks such as Sales and Operations Planning (S&OP) and Integrated Business Planning (IBP) significantly enhances alignment across business functions, enabling proactive management of risks and opportunities. Ultimately, successful end-to-end planning equips chemical manufacturers with the resilience and flexibility necessary to thrive amidst market volatility, safeguard profitability, and sustain high levels of customer satisfaction.

Lesson Takeaways:

-

Effective supply chain planning in the chemical industry requires detailed management of global sourcing, production complexity, regulatory compliance, and logistical challenges.

-

Demand forecasting accuracy and strategic inventory optimization are critical to maintaining service levels, cost-efficiency, and safety.

-

Integration of cross-functional planning frameworks like S&OP and IBP significantly enhances organizational alignment, agility, and decision-making capabilities.

-

Optimized logistics management involves strategically selecting transportation modes and multimodal solutions to balance speed, cost, safety, and regulatory adherence.

-

Comprehensive and integrated planning approaches empower chemical companies to proactively manage uncertainties, maximize resource utilization, maintain compliance, and achieve competitive advantage and sustained profitability.