Lesson Title: Sales and Operations Planning (S&OP) in the Chemical Industry

Lesson Description:

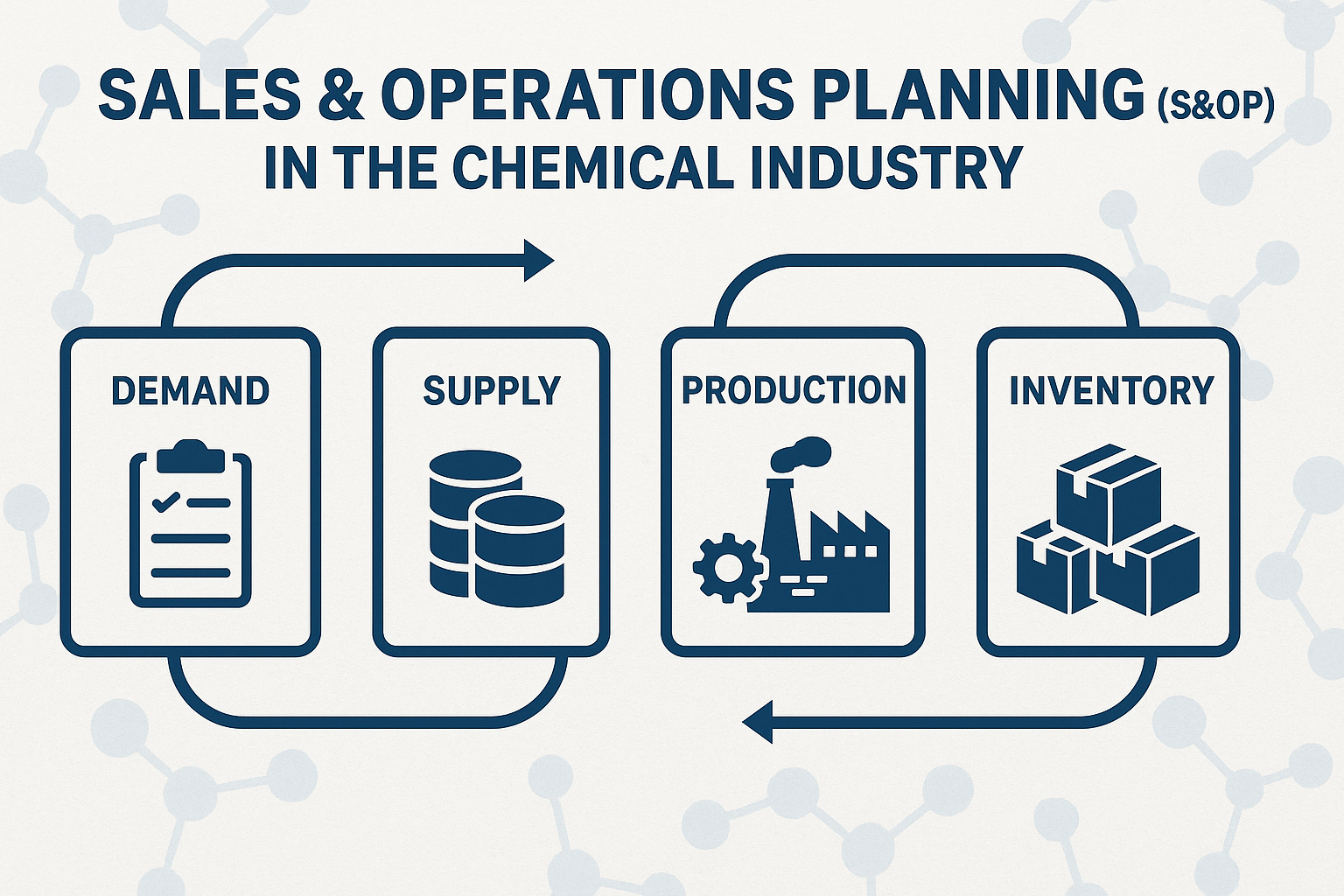

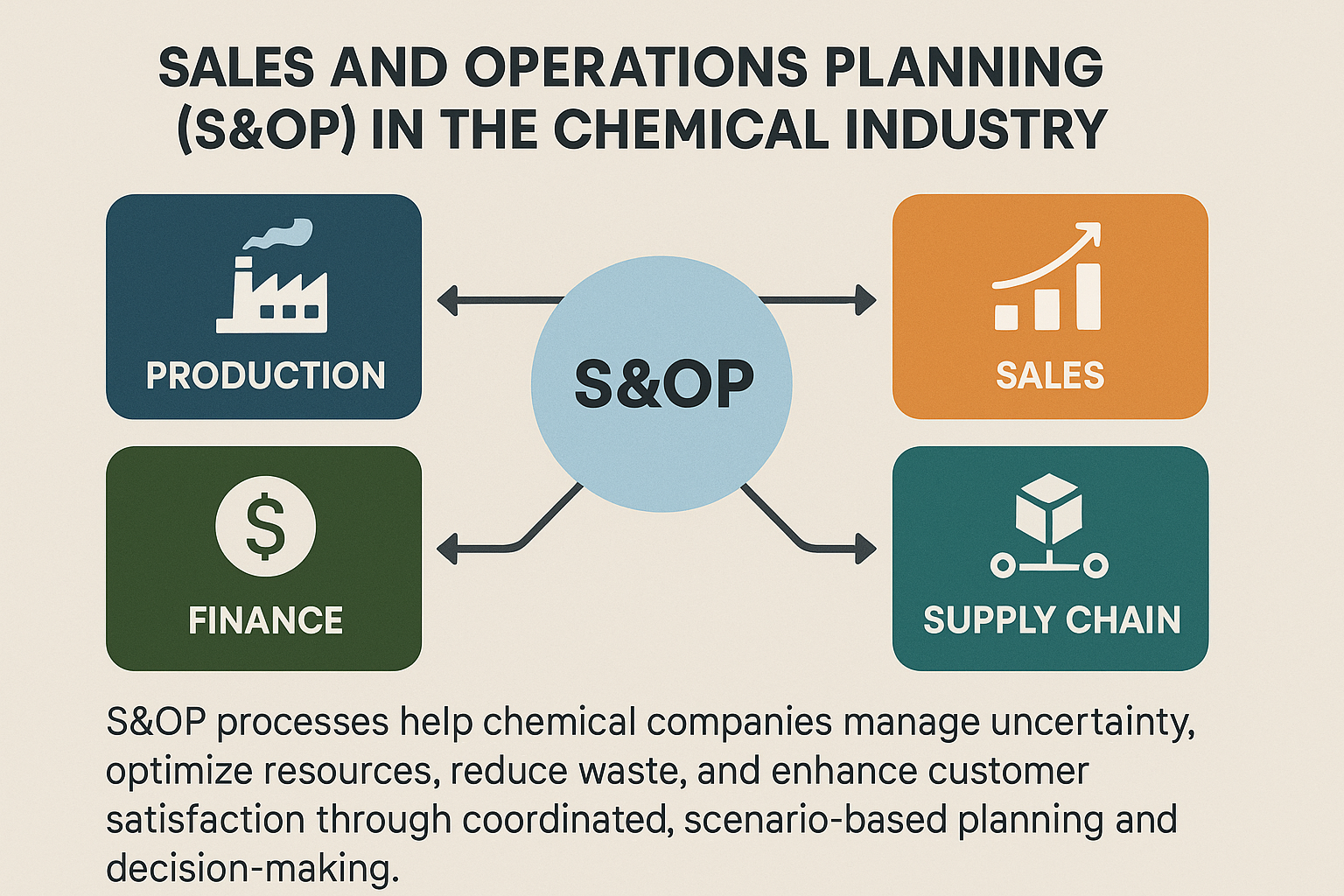

Sales and Operations Planning (S&OP) in the chemical industry integrates various organizational functions—production, sales, finance, and supply chain—to balance customer demand, production capabilities, and financial objectives. Effective S&OP processes help chemical companies manage uncertainty, optimize resources, reduce waste, and enhance customer satisfaction through coordinated, scenario-based planning and decision-making.

Lesson Learning Objectives:

By the end of this lesson, participants will be able to:

-

Explain the critical role of S&OP in aligning different business functions within chemical companies.

-

Describe the steps involved in the S&OP process specific to the chemical industry.

-

Utilize scenario-based planning to anticipate and effectively respond to market and operational uncertainties.

-

Understand the integration of S&OP with financial and strategic goals through Integrated Business Planning (IBP).

Lesson Key Points:

-

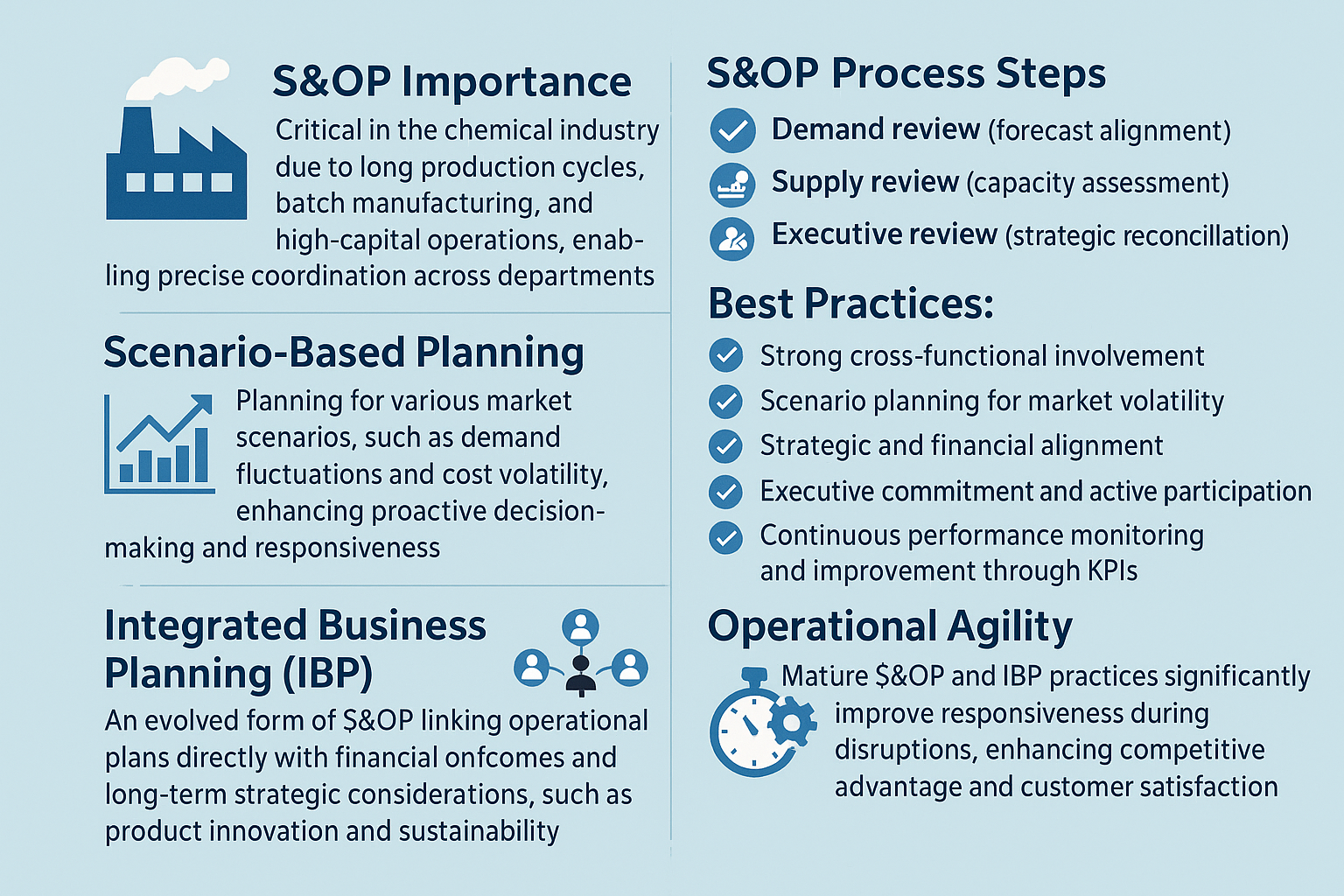

S&OP Importance: Critical in the chemical industry due to long production cycles, batch manufacturing, and high-capital operations, enabling precise coordination across departments.

-

S&OP Process Steps: Demand review (forecast alignment), supply review (capacity assessment), and executive review (strategic reconciliation).

-

Scenario-Based Planning: Planning for various market scenarios, such as demand fluctuations and cost volatility, enhancing proactive decision-making and responsiveness.

-

Cross-Functional Collaboration: Essential sharing of information among sales, marketing, production, finance, and supply chain teams, ensuring comprehensive and accurate planning.

-

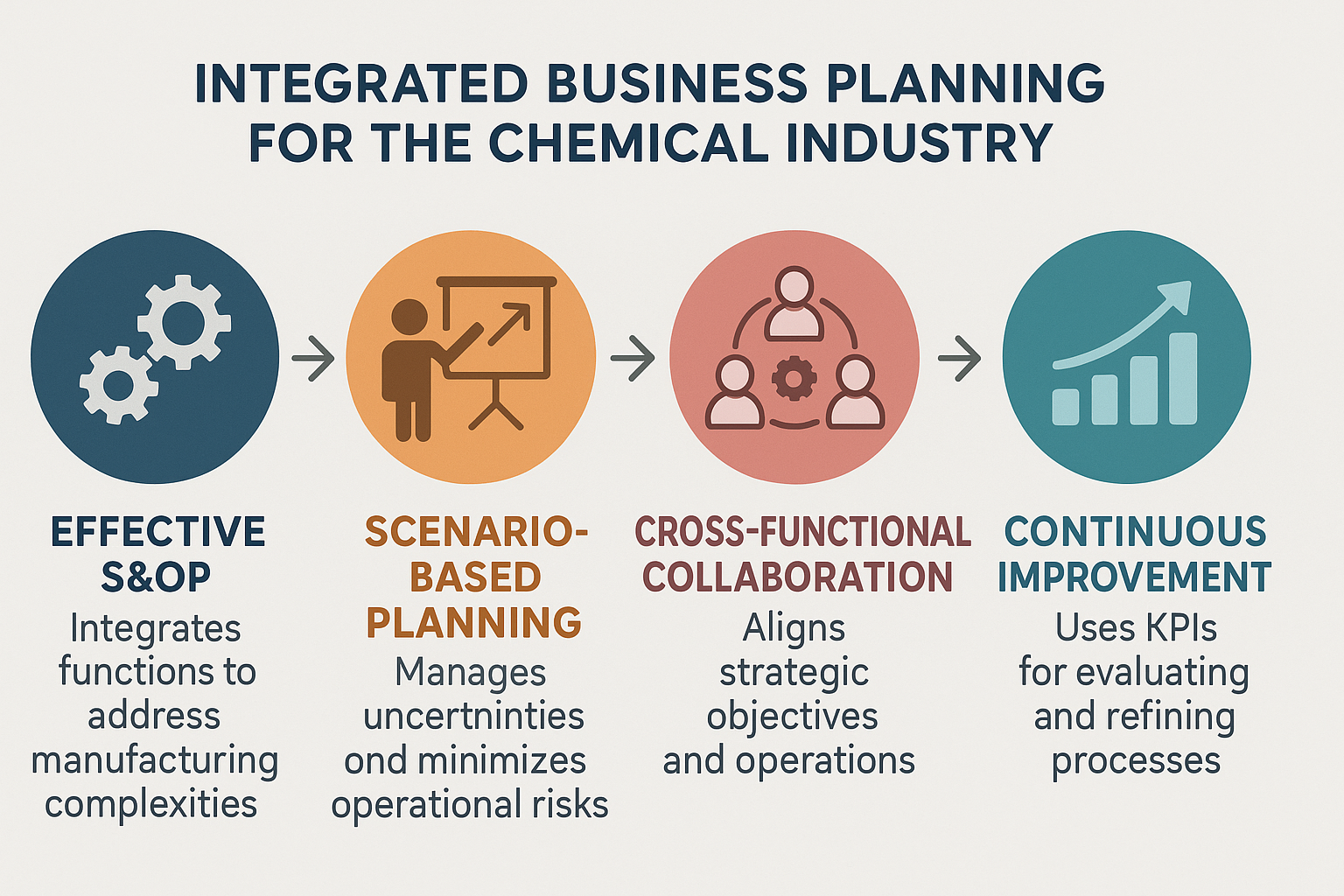

Integrated Business Planning (IBP): An evolved form of S&OP linking operational plans directly with financial outcomes and long-term strategic considerations, such as product innovation and sustainability.

-

Best Practices:

-

Strong cross-functional involvement

-

Scenario planning for market volatility

-

Strategic and financial alignment

-

Executive commitment and active participation

-

Continuous performance monitoring and improvement through KPIs

-

-

Operational Agility: Mature S&OP and IBP practices significantly improve responsiveness during disruptions, enhancing competitive advantage and customer satisfaction.

Lesson Summary:

Sales and Operations Planning (S&OP) is a foundational management process for chemical companies, effectively aligning multiple organizational functions—sales, production, finance, and supply chain—into a unified operational strategy. Due to the industry’s inherent complexities, such as extended production cycles, batch processing, high capital investments, and significant resource commitments, S&OP serves as an essential planning mechanism. The S&OP cycle encompasses demand forecasting, supply assessments, and executive oversight to reconcile strategic business goals and market realities. Advanced scenario-based planning methods enable chemical companies to anticipate market changes, adapt quickly to external disruptions, and proactively manage operational risks. Comprehensive cross-functional collaboration and executive engagement underpin successful S&OP implementations, ensuring alignment with both immediate operational needs and long-term financial and strategic objectives.

Lesson Takeaways:

-

Effective S&OP integrates all key organizational functions to address the unique complexities of chemical manufacturing, such as lengthy production processes and substantial capital expenditures.

-

Utilizing scenario-based planning within S&OP equips chemical companies to proactively manage uncertainties, respond effectively to disruptions, and minimize operational risks.

-

Cross-functional collaboration, combined with robust executive involvement, is critical in aligning strategic objectives and operational realities, ensuring efficient decision-making and resource optimization.

-

Integrated Business Planning (IBP) extends S&OP by explicitly linking operational plans to financial and strategic outcomes, significantly improving organizational agility, profitability, and market responsiveness.

-

Continuous evaluation, performance tracking, and refinement of S&OP processes through relevant KPIs drive sustained improvements, enabling chemical companies to maintain competitive advantage and achieve consistent customer satisfaction.